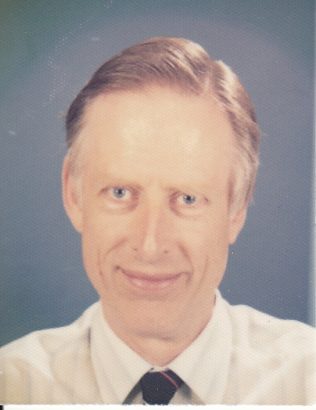

Michael Hogan

Apprentice 1953-1957

Michael attended Cheltenham College where he was keen on persuing a career in Engineering. In the 1950s, Fielding and Platt wanted to recruit people to go into the production side of the business and they went to the college to find potential apprentices.

Fielding and Platt and Cheltenham College

Michael had been on work experience at Fielding’s before joining the company as an apprentice. The work experience mostly involved “standing around watching” as well as “carrying and holding implements”.

However he achieved the appropriate O-Levels, including Geometrical and Mechanical Drawing, Additional Mathematics, and Physics. Because Michael attained these, he was excused the first year of the apprenticeship, so completed a 4-year instead of a 5-year apprenticeship.

Interestingly, Michael had already made things for Fielding’s in Cheltenham College’s workshop.

“I used to make things in the workshop … I also made things there for Fielding and Platt because [Cheltenham College] had an agreement that they would make certain bits and pieces for Fielding and Platt just to boost the funds.”

Fred Shelley, Ronnie Lane, Nigel Scott, and Michael himself all went to Fielding’s from Cheltenham College.

Excellent lunch in the New Inn

Michael was interviewed for the apprenticeship at Fielding’s by the Personnel Manager at the time, Mark Phillips. The interview process involved “an excellent lunch in the New Inn” which was “in those days very smart” with “waiters in black tail coats and silver service”. After all the formalities of the day, Michael was then signed over to begin his apprenticeship with Bert Ravenhill in the Craft School.

Bert Ravenhill

Bert Ravenhill was the Instructor in the Craft School and Michael recalls that he “ruled it with a rod of iron!”. Under Bert’s leadership, the Craft School had a disciplined air.

“Bert was rather good at shouting at people … I can remember him saying to me ‘I wish I was a Sergeant Major’ when he was having a go at another apprentice about something!”

Bert was assisted by John Davis who was the Senior Apprentice Instructor.

After six months in the Craft School, Michael recalls that the apprentices went onto work in a range of areas around the factory every six months “in order to give them a rounder view of the business”. In clip 5, Michael remembers his time as an apprentice in the Drawing Office.

Making “foreigners” and Jim Fielding’s golf trolley

One of the perks of working in the factory was that, occasionally, people found time to make bits and pieces for themselves. These were called “foreigners”. Michael remembers making some bits and pieces for his Vincent Blackshadow Series C motorbike.

“I remember somebody saying ‘I heard you going out on that motor bike of yours last night … it went F&P F&P F&P!’ I thought that was a rather splendid joke on the fact that I had made bits for it and there it was going out making that noise… so he said!”

One of the best “foreigners” Michael worked on was a golf trolley for the Managing Director Jim Fielding. It was really sophisticated.

“The brass foundry did the aluminium castings for that golf trolley, the welders did the tubular steel bit, and I think we had to buy the wheels … It must have cost a fortune in those days and it probably weighed a ton as well! I don’t know if he ever used it or not but anyway he had one made and that was the M.D.’s golf trolley and woe betide anybody who made a mess of it!”

The trolley was put together in the Craft School in bits and pieces over a number of weeks.

Apprenticeships and strikes

Sometime during his apprenticeship Michael remembers that there was one day strike over pay.

Apprentices were not permitted to strike, so Michael remembers what happened in the Works on the day.

“I can remember being in the Machine Shop and I think Jim Fielding also got going in the Machine Shop on the day doing a job. And I can remember the Staff who could drive a lathe and who could drive machines, they also helped out”

The apprentices were given a lecture by Mark Phillips explaining why they weren’t allowed to strike. He advised them that to get through the picket lines they would have to say that they were “an apprentice at Fielding and Platt” and that they would then be let through.

When Michael started as an apprentice he was paid £2 10s per week. His mother paid for his digs which were £3 per week. As Michael explains, an apprentice’s wage wasn’t really meant to be something you could live on because you were meant to be living with your parents.

More memories of Michael’s time in the Fitting Shops in the 1950s coming soon!

If you remember Michael or if his reminiscences bring back memories of the people, places, and machines at Fielding’s please share your memories by clicking on the words Add a comment about this page below.

Comments about this page

Yes Mike, I do remember the golf trolley for Jim Fielding. It was a collapsible one. We were only given sketches for manufacture of the individual parts but no arrangement drawings to assist in assembly. That caused a few problems. We must have done a good job because I recall we made two more, one I believe was for Peter Julier, the Purchasing Manager. Another requirement was for a swivelling/tilting mechanism to connect the great man’s camera to his tripod.. The first one didn’t meet requirements so we made a second one which did. I think I still have the original one somewhere in the depth of my garage. I also remember Mike giving me a lift to the sports field a couple of times on the Vincent. Happy times!!

Add a comment about this page